A Hidden Gem: An Insider’s Look at Chapman Manufacturing

January 8th, 2024

7 minute read

Most people who have done even a minimal amount of home gunsmithing have no doubt heard about Chapman Manufacturing’s quarter-inch drive, hollow ground screwdriver bits, midget ratchets and driver handles, which have been made in America since John W. Chapman founded the company in 1936.

The company has been at the same Durham Connecticut location since about 1965, which is just around the corner from the garage where the company began making tools. I was fortunate to recently have had the privilege of touring the Chapman Manufacturing facility.

Continuing the Tradition

The current majority owner of Chapman, Tracy Camassar, purchased the business from the second owners in 2012 after having been employed there for several years. Prior to Chapman Tracy worked in manufacturing, and when she arrived at Chapman and saw familiar posters of TRW Tool and Die charts, she knew she was in a good place.

Tracy told me that she had the benefit of working with Mr. Bill and Mrs. Doris Levee — the second owners of Chapman Manufacturing. Bill, an engineer bought the business from Mr. Chapman. Thus, Tracy is only one or two steps removed from the inventor.

Chapman tools have always been unique and innovative, but the new owners brought new ideas to an old (but successful) business. Tracy said that things like e-commerce as well as different case colors and sizes as well as adding to the already large line of quarter inch hex drive (Allen) bits has helped the brand grow among existing customers as well as adding new ones.

On my visit to Chapman, I was fortunate enough to spend some quality time with Joel Camassar, Tracy’s son. Joel is familiar with all aspects of marketing, manufacturing, packing and shipping.

The Foundation

The company has a strong “Buy American” ethos. Chapman products are not only made in America — but all of the raw materials used to make the tools are also American-made. The bits and extensions are made from USA tool steel. Even the plastic cases, cutting oils and packaging materials are made in America. Tracy told me that they pay careful attention to their suppliers and if something changes, Chapman will not hesitate to make a change to keep their tools 100% American-made. This alone is a full-time job.

I have toured other metal working factories, and while the entire Chapman operation is impressive, what impressed me the most was the cleanliness of the plant and the fact that Chapman has little to no trash to dispose of. Boxes are shredded and reused as packing material for outbound shipments, metal shavings and chips are removed from cutting oil and the cleaned oil is then reused — for up to 10 years! Joel told me it takes a long time and tens of thousands of uses for cutting oil to become unusable. The chips are sold off to a steel recycler to be remade into other steel products.

Even the outside of the Chapman factory is environmentally friendly. They have a pollinator garden right outside the shipping and receiving door with all sorts of plants.

Moving Forward

Joel told me that some of the more recent additions to the product line have come from customer requests. Older Chapman tool sets came in a red box that resembled a jewelry box. Newer sets were sold in a yellow box. Joel told me that the decision to offer blue, red and orange boxes in addition to the familiar yellow was made because customers told him that in larger shops where many people had Chapman tool sets, it was difficult to tell each machinist’s set apart from the others.

Many people learned about Chapman tools from their fathers and grandfathers, and in some cases the tools are handed down from one generation to the next. Hence, the option to purchase a Chapman set in a wooden, heirloom case that is both functional and handsome to display in a shop or garage was introduced because of customer feedback.

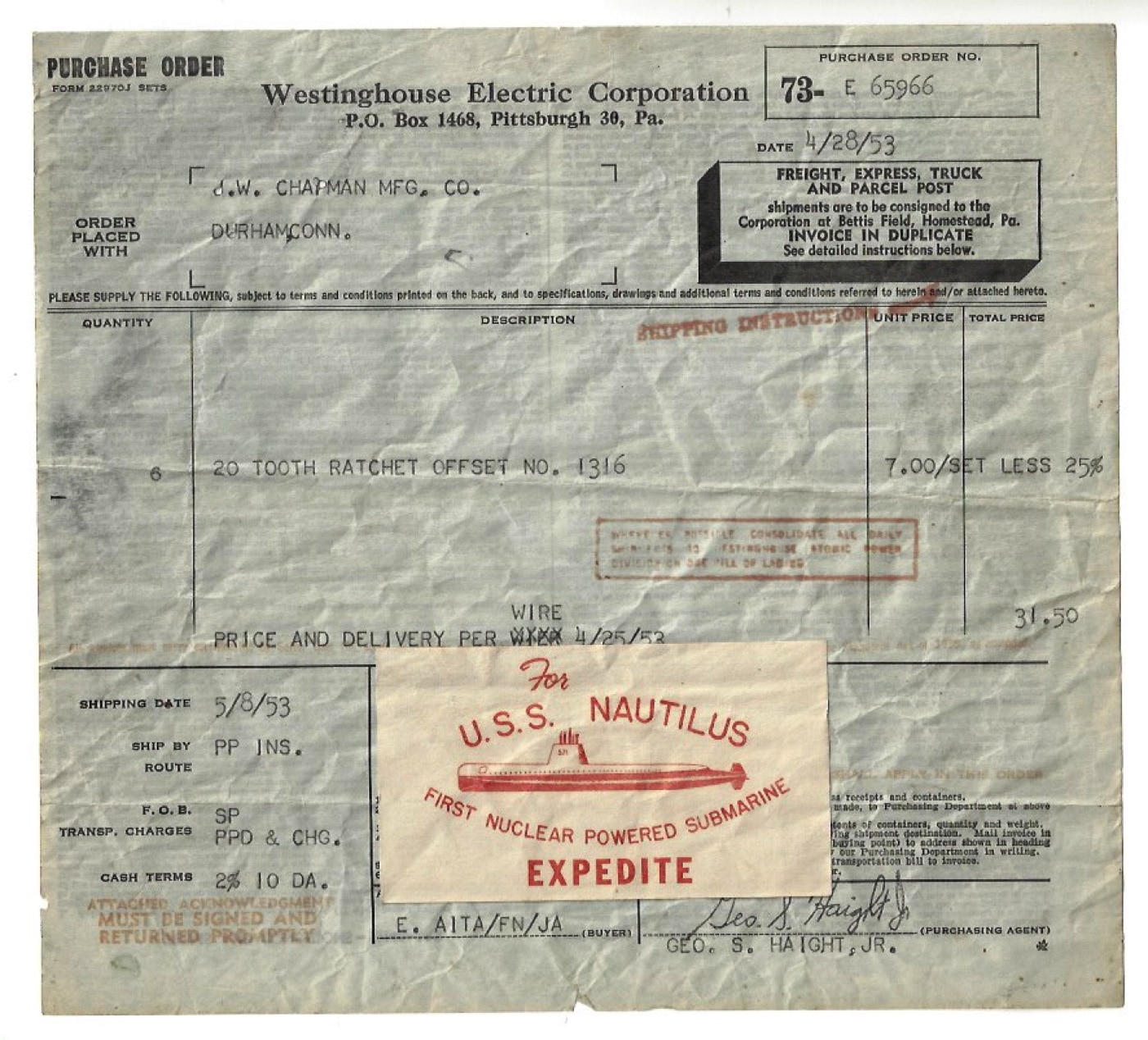

In addition to gunsmiths, gun manufacturers and hobbyists, Chapman supplies every branch of the U.S. Military and the United States Postal Service. In 1953, the United States Navy specifically requested six Chapman sets to sail aboard the USS Nautilus — America’s first nuclear powered submarine.

They also supply tools to companies that are in the business of repairing medical and dental equipment, audio visual equipment or require the need to work in tight spaces. Despite this success and legions of satisfied customers (including this author), Chapman Manufacturing always seeks new markets for their American-made tools.

Chapman uses its own tools to keep the plant’s machinery running at peak efficiency. The company also has, on site, a complete machine shop to fabricate the parts and tools needed to manufacture Chapman screwdriver bits. Chances are, if you have to install or remove a delicate fastener — Chapman makes a tool to turn it.

While the on-site machine shop still requires manual set-up, one of the huge changes Tracy made was to invest in CNC machinery. Instead of having an employee set up and operate a single machine, these automated wonders of manufacturing, once set up run themselves — automatically.

Best of the Best?

Several design features make Chapman tools different, and in the opinion of many, better than other, similar tools. The bits are engineered to break before the fasteners that they are sized to turn. In addition, a Chapman hollow ground screwdriver bit is designed to properly fit a fastener which means that in most cases, a Chapman bit will not mar or otherwise damage a screw.

The price point of individual Chapman bits is low enough ($2.95) that if a bit breaks, it will likely save the more expensive firearm part. On an older firearm, for which spare parts are hard to find, this matters — a lot. Joel told me that Chapman management understands that many times a single bit will break or get lost, so the company will happily sell individual bits to replace lost or damaged bits, or to expand an older set with more sizes.

Chapman bits and extensions are black oxide coated to reduce the chances of rusting. The coating does not increase the size of the bit — in other words, Chapman bits properly fit fasteners. Another unique Chapman feature is a ball detent to keep the bit from dropping out of the driver. In my opinion, the ball detent is superior to a magnet which can interfere with sensitive electronic equipment. Additionally, the extensions and driver handles have a set screw to make absolutely certain the bit won’t fall out in use.

The ends of the bits are knurled, which makes it easy to tighten fasteners with just fingertip pressure. The Chapman CM-13 mini ratchet can withstand up to 200 inch pounds of torque, an amount that far exceeds most firearms uses — most scope caps are torqued to 20 — 25 inch pounds and Picatinny style bases to about 65 inch pounds.

For a long time, the standard Chapman extension was 3 5/8 inches long. The company now offers two and six inch extensions, (I prefer the two inch). Another one of the newer products is an option to order a CM-13 mini ratchet with a soft rubber coating applied to the handle, customers can choose any or all of three colors.

I have many tools that came in nice plastic cases, that have a plastic strip for a hinge that will not allow the case to stay open on the workbench. Such a case can be frustrating and slow down projects; especially when my hands are oily and I am juggling several small parts. Chapman cases are designed to be efficient; they have an actual hinge on the top that allows the case to stay open and provide easy access to the tools. As I explained above, there is little to no waste at the Chapman factory. The company is so focused on efficiency that the plastic cases were designed to fit into a U.S. Mail Small Priority Mail flat rate box for cost-efficient shipping!

During World War II, Chapman Tools were considered so vital to the war effort that the U.S. Government assigned an OPA Price Ceiling of $6 per set, (Office of Price Administration).

Conclusion

Chapman Manufacturing is, in every sense, a family business. Tracy’s husband is an accountant and takes care of the taxes and payroll. Joel handles regulatory compliance and sales. Tracy as the majority owner, oversees the entire business and spends her time planning special projects such as a new heat treater.

I have used Chapman tools for over 30 years and have never been disappointed. I have no reservations about recommending them to The Armory Life readers. The fastest, most efficient way to obtain Chapman tools, whether a single bit, or a complete set that might not be on a local retailer’s shelf is directly from Chapman. They take phone orders (860-349-9228) from 8am–3pm, Eastern Time, Monday through Friday as well as mail and internet orders.

Editor’s Note: Be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in!

Join the Discussion

Featured in this article

Continue Reading

Did you enjoy this article?

91

91