Essential Tools for Home Gun Maintenance

October 27th, 2023

7 minute read

As a group, gun owners for the most part are mechanically inclined and like to tinker. Many folks prefer tools that make jobs easier to complete. Several students who have attended firearms training courses I taught brought in firearms with damage that was avoidable with the use of the proper tools. And this was damage that in many cases far exceeds the cost of a specialized tool.

The editors asked me to give The Armory Life readers a description of tools that are needed for the maintenance and cleaning of SAINT and M1A rifles as well as 1911 pistols. I prefer to always to use the correct tool for the job. I do not improvise because the best tools will yield the best results.

This is not a “how to clean” article or a “home gunsmithing article”; topics which, depending upon the firearm being worked on, could easily be a series of lengthy articles. The purpose of this article is to explain what tools a gun owner needs to properly maintain firearms at home — and which are necessary and which are simply “nice to have”.

The Necessaries

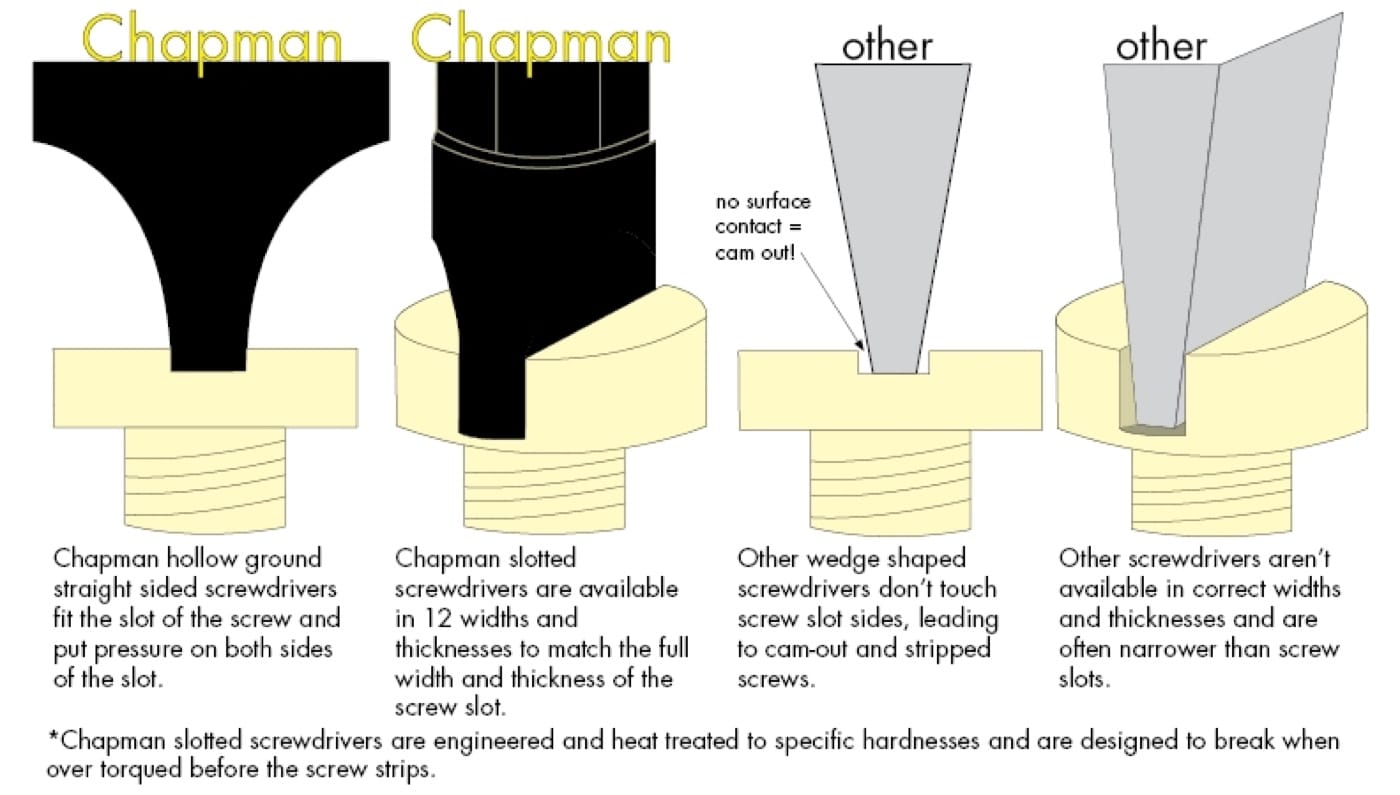

First and foremost, a high-quality set of hollow-ground screwdrivers is a necessity to prevent damaging fasteners. I own several sets: a Chapman Manufacturing set, which is non-magnetic; and a Brownell’s set because it is magnetic (Brownell’s also sells a 1911 grip bushing driver that fits the Magna-Tip handles). I also own a Wheeler Engineering set that includes numerous firearm(s)-specific bits. In addition to traditional flat and Philips head bits, all three of these sets include Allen and Torx (star) bits. I have a 10-8 Performance non-marring armorer tool that is useful for prying, scraping and pushing small parts without damaging them.

Another necessary tool is a gun vise. I have used several over the years, but my current go-to gun vise is a Tipton Ultra Gun Vise. This unit, which has a virtually unlimited range of adjustments, will hold a traditional full-stocked bolt-action rifle, a SAINT AR-type rifle, an AR upper receiver only, and handguns.

Most important to me is that the Tipton Ultra Vise will securely hold an M1A — turned upside down so that bore solvent does not drip into the gas system. With respect to bore solvents, I prefer Hoppes #9 because it has always worked well for removing copper and carbon fouling, so I see no reason to change.

When I am cleaning a rifle, I prefer a tight patch-to-bore fit; this requires some effort to push the solvent-soaked patch through the bore; the last thing I want to happen is to push a rifle off the workbench — a quality gun vise will prevent that unfortunate occurrence.

M1A rifles need grease not oil, and for that I use Mil-Comm TW-25B, the same product I use on 1911 frame rails. A small and inexpensive tool called a Bolt Roller Greaser should be in the toolbox of any M1A owner; it makes greasing the bolt fast, easy and thorough.

A quality gun vise is needed to hold a rifle in place; not only for cleaning, but to properly mount scopes or change sights. It is not difficult to mount a scope — especially on a modern rifle like a SAINT. However, to make sure that rings are not over- or under-tightened, a torque wrench that measures in inch pounds is an essential tool. I use an older Brownell’s model that works with Magna-Tip bits and 3/8 drive sockets.

I clean all AR-type rifles the same way (for that matter I clean all rifles the same way). It doesn’t matter if I’m cleaning a heavily upgraded SAINT Edge or a SAINT M-Lok. I use a bore guide to keep the cleaning rod perfectly centered inside the barrel, and with the exception of the M1A, I push a properly sized cleaning patch through the bore in the same direction as the bullet travels.

I prefer J. Dewey cleaning rods. They make brass rods as well as steel rods that have a nylon coating. Nylon-coated or brass is a matter of personal preference. Both are designed to prevent barrel damage and are sold in various lengths and diameters. Of equal importance, rifle-length J. Dewey rods have ball bearings inside the handle that allow the rod to spin with the barrel twist. In addition to rods, J. Dewey manufactures a complete line of jags, loops, brushes, bore guides and assorted other high-quality gun cleaning tools.

Foundations

A rubber mat makes gun maintenance a little more pleasant. My preferred mat is the Lyman Essential Rifle Maintenance Mat. This mat is 36” long by 10” wide and provides plenty of space to spread out tools and cleaning supplies. The molded-in compartments keep small parts from rolling away, which is especially useful when cleaning on the tailgate of a pickup truck that might not be parked perfectly level. The Lyman mat is made from synthetic rubber, and I’ve found that solvents wipe off easily.

While not a gun maintenance tool, the Husky Portable Jobsite Workbench sold by Home Depot allows me to set up and clean guns anywhere. During the summer and fall, I prefer to clean and maintain firearms outdoors due to the odors of cleaning products. Oils and solvents easily wipe off the hard plastic surface. This very sturdy portable table has a weight capacity of 1,500 lbs. and will handle any firearms-related task with ease.

When working with AR-type rifles that have plastic handguards, a handguard removal tool is nice to have. There are many manufacturers who sell this type of tool, which hooks into the magazine well and gives the user the needed leverage and “third hand” to compress the Delta Ring so that the handguards can be easily removed and replaced.

I like very clean guns. Three areas on 1911 pistols that can be hard to clean are the frame and slide rails and inside the firing pin and extractor channels. I have a Channel Lock Hook and Pick set that works well for the frame and slide rails. I just wrap a clean patch around the 90-degree hook and run it along each rail. In my experience, this setup works better than a Q-tip that could break under pressure.

I use a non-marring brass punch to press in the firing pin so I can remove the stop, firing pin and spring. I then use the 90-degree hook to pull the extractor out of its channel. Both of these channels are small, and I recommend cleaning them every 2,000 rounds by sliding a Q-Tip in and out. Another useful 1911 tool is a barrel bushing wrench.

Quality punches are essential. If you are on a budget and don’t want to buy a complete set, Brownell’s sells most of the common sizes individually — both in brass and steel.

A tool that is in the category of “nice to have but how did I ever live without it” is a good bench vise and a set or two of padded jaws. Because space in my shop and on workbenches is at a premium, I bolted my old Starrett vise to a piece of 2X6 lumber. When I need to use the vise, I C-clamp the 2X6 lumber to the workbench. This setup saves space because when I’m not using the vise, it is stored out of the way. The C-clamp has not failed me — even when torquing barrel nuts on AR-type rifles.

There are many different holding fixtures for AR-type rifles that allow a bench vise to hold the upper receiver in place for maintenance or scope mounting. I am partial to the Precision Reflex M16-AR15 Upper Receiver Assembly Vise Block. This specific tool can either be clamped onto the Picatinny rail on the top of the upper receiver or attached to the take-down and pivot pin holes that are used to mate the upper and lower receivers. Whichever mounting option is chosen, there is plenty of room to use a bore guide to keep the cleaning rod perfectly centered inside the barrel.

Conclusion

If you take care of your firearms, they will last and work reliably for generations. The tools and techniques shared here should by no means be considered an exhaustive list or even an exclusive list. They are, however, intended to provide readers with those items that the author has found to be the easiest and most efficient to use.

Editor’s Note: Please be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in and discuss this article and much more!

Join the Discussion

Featured in this article

Continue Reading

Did you enjoy this article?

101

101