Heirloom Precision

Custom SA-35 —

A Millionaire’s Gun?

June 8th, 2023

9 minute read

Have you ever owned something really nice? I don’t mean good, or even great. I’m talking about truly remarkable. I have handled — and shot — my fair share of guns over the years, so I think I have a pretty good idea of what works and what doesn’t. I’ve also worked on many of them myself, so also I have a reasonably good idea of what’s involved in customizing them.

First and foremost, a gun is a tool, so function is paramount. To have one that meets that requirement necessitates not only good design, but proper production of that design at scale, and — presumably — all done at a reasonable price. This is much easier said than done.

A company like Springfield Armory works very hard to make great guns at great prices, and at this it clearly succeeds. To achieve this, it produces large numbers of them on very expensive equipment to the tightest tolerances possible, all while keeping costs to a manageable level. The end result is a firearm that transcends just basic function, offering you a gun that is more than simply reliable. It features excellent quality as well as notable attention to detail.

But what if there were no “cap” on what the firearm could cost, or the amount of hand labor that could be put into it? It’s at this point we move into the realm of “custom” firearms.

A Singular Focus

In the past, gunsmiths could find themselves addressing issues with firearms regarding their basic design and function. This could include projects of tuning a gun to run a specific loading to tweaking one for more capabilities in a specialized role. However, the advent of precision CNC machining has made getting a “basic” gun with advanced features and reliable functioning much more common.

A Springfield Armory 1911 Ronin is an excellent example of this. Priced at an MSRP of $917, it gives you excellent parts and pieces (forged frames, slides and barrels) so expertly assembled that someone like me could win national and world championships in competition pistol shooting with it right out of the box. Sending this one to a gunsmith for tuning or tweaking could arguably be a waste of your money. So, what to do with these gunsmiths’ idle hands?

How about having an experienced artisan who truly loves his craft, and one with a focus on the most minute of details, apply endless hours of attention to a firearm? I am not talking about them focusing on the function or design of the pistol, but strictly on the details. This is the type of customer for whom price is not an object, and one who demands a master of the trade work on their firearm.

They want not only the big things to be right, but also the tiniest of details — down to the smallest minutiae. Let’s be frank, these are things that won’t show up in our normal measurements of performance like accuracy, reliability or durability. This person wants to be able to look over every surface of the firearm with a 10X loop and be incapable of finding a single flaw, inside or out.

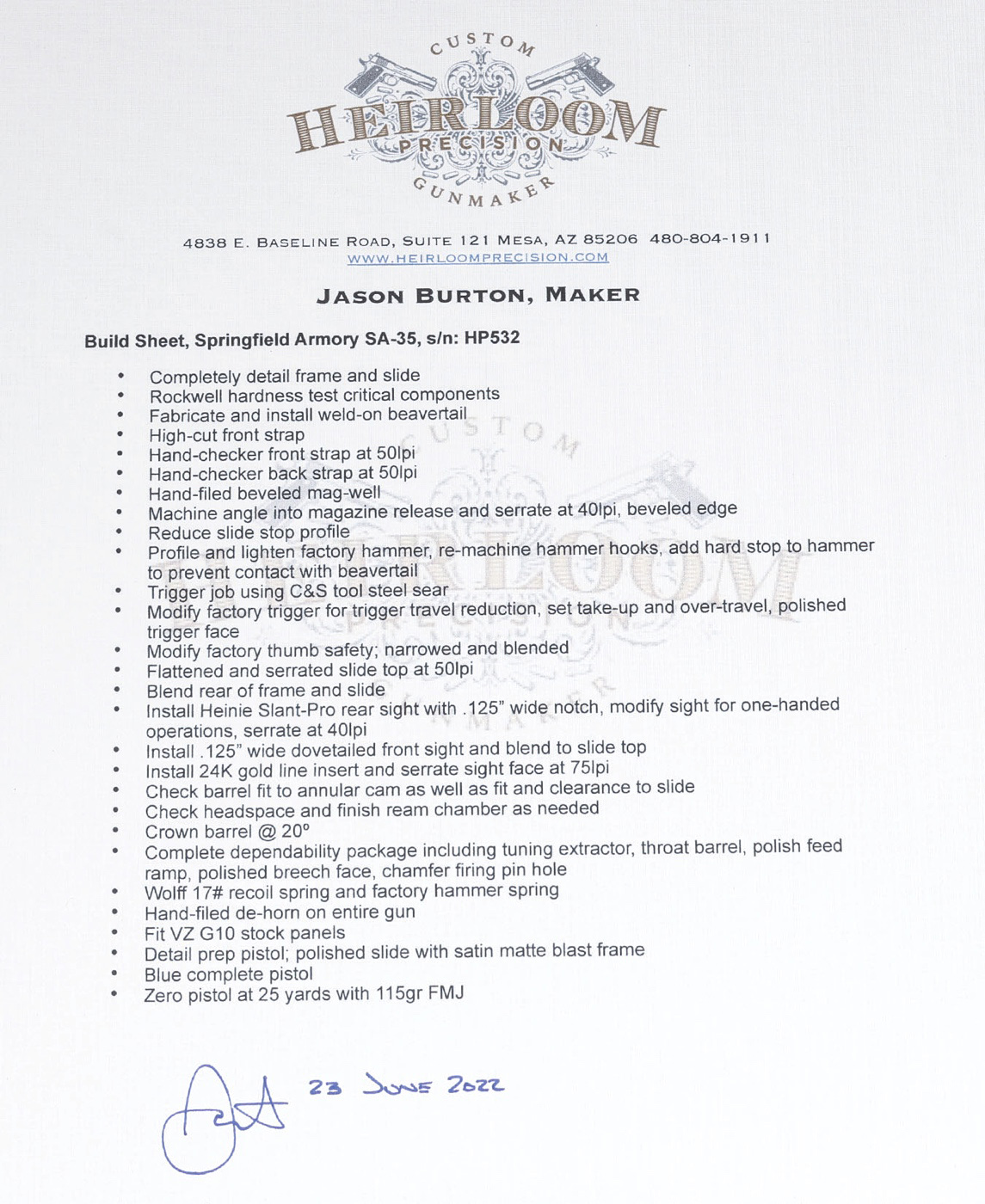

For this customer, I would introduce Jason Burton of Heirloom Precision (see our full interview with Mr. Burton here). Simply put, Heirloom Precision is Jason. There is no major production facility backing him up. He’s not sending frames out to be checkered, etc. He does every step of the work with his own two hands the old-fashioned way. You know, that whole “sweat and tears” approach? For him, this way is the only way to produce a product that would satisfy his personal demand for absolute perfection. Jason has taken the perfection of detail in a custom 1911 to a degree that few can reach.

Solid Foundation

When Springfield Armory introduced the 9mm SA-35, I was ecstatic. This is a firearm design I have always deeply admired. While I already had a few custom versions of this gun in my collection, I know that this one from Springfield would offer shooters a great adaptation of the design with solid, high-quality parts and rugged primary components like the slide, frame and barrel.

The P-35 design was basically the last project on which the legendary John Browning worked, and many argue it is the perfect gun for the 9mm cartridge. The pistol is downright svelte in the hand, while still allowing for a 13-round capacity in the original configuration, and a flush-fitting 15-round-capacity magazine in the new SA-35. I’d argue that if the 9mm is your round of choice and you want a single-action firearm, it’s hard to beat this pistol.

The only downside to the original is that they could have slides and frames that are not quite up to handling high round counts. The Springfield Armory SA-35’s use of forged parts addresses this concern, while its other tweaks to the design (like the aforementioned increased magazine capacity, along with other enhancements like improved ergonomics, better sights and no magazine disconnect safety to bring it in line with Springfield’s other offerings, etc.) really help take it to the next level.

So, Springfield did all the big (and several of the “little”) things for you on the P-35 design. But what about all those extra tweaks you might want that would not have been even remotely possible for Springfield to do and still offer the gun at an MSRP of $799?

Frankly, as good a design as the P-35 is, it can be very hard to do custom work on. Checkering, for instance. The gun has a remarkably slim and petite grip frame area for being a double-column magazine design. This is why it feels so good in the hand. But, it also requires you to do a great deal of measuring before you do any cutting. It’s very difficult to do it in a production environment with machinery because you have to measure it over and over again to ensure you don’t cut too much away.

The trigger is another unique part of the design. Springfield managed to take what has been known as a very mediocre trigger in the original design and make it excellent. Want to take it to the next level beyond that? It requires an expert that understands the design and how best to approach it.

Snagging a Master

This brings us back to my buddy, Jason. Luckily, Jason understands this design extraordinarily well. While he may be known for his work on the 1911, he is no stranger to the P-35 platform. In fact, he is quite a fan.

It was during a recent conversation with him that we arrived at the project you are reading about today. I had been curious about what would happen if you gave one of the new, improved SA-35 pistols to a magician like Jason Burton. I brought up the subject of him working on an SA-35 and making it exactly the way he would want it. He was intrigued.

Jason looked the gun over in detail and was very impressed, especially after he measured the Rockwell hardness of the slide and the frame. He told me it is by far the hardest ones of these from this design he had ever seen. Right off the bat, we were ahead of the game. He also noted that the internal machining of the pistol was extremely good. This, combined with the proper hardness of the slide and frame, ensured it could be a great canvas for his artistic efforts.

The more he inspected the pistol, the more interested in the project he became. Soon, he had agreed to take on the project. Basically, Jason went to town on the pistol. He worked on it for months, doing it as a side job and fitting in hours on the weekends to get it done.

I’ve known Jason for a while, and I can always tell when he is “into” a project. How? because he wants to talk about it. And we talked a lot about this gun. I had the privilege of seeing it being built, and I was able to see much of the incredible detail of effort Jason put into the pistol. I picked up that many, many hours of obsessive attention to detail were being applied to this pistol. This included inspecting it, polishing it and removing minute scratches that I often wondered if only he was seeing. I couldn’t see them, but he could.

And when it was finished, it was easy to tell it was something truly special. Not just that it was put together well, which it is, but that the whole package was even better to look at closely than it was at a distance. In comparison, if you were to look at one of my competition pistols I have been shooting for many years, it would be at the other end of the spectrum. It would have dings and scratches, and you would see where I have taken a belt sander to it as well as all the little tweaks and mods I apply to it to make sure it fits me perfectly. I do all this work as expediently as possible with little regard for what it looks like, and it shows. This is not Jason’s approach. Honestly, this custom SA-35 should be in a museum or shadow box in some millionaire’s gun room. I think the phrase “exquisite in detail” is appropriate here.

From giving it a thorough dehorning to modifying just about every angle and shape of control on the gun, Burton tweaked and tuned it to his heart’s desire. What can a master do when you truly set him loose? I think the results speak for themselves.

An Irresistible Pull

I know some of you are going to cringe at what I am getting ready to write, but I could not resist. I shot the gun. And the old adage of the “proof is in the pudding” could not be more true here. The gun functioned perfectly, of course, and it was very accurate. But there is more. It just felt … perfect. I don’t really know how to better describe it. It was a joy to just be able to hold it, and it was extremely satisfying to shoot.

The coolest thing about a custom gun like this is that even though it is extraordinarily valuable and quite expensive to make, in the realm of “very nice things” it is relatively inexpensive. You’d spend hundreds of thousands of dollars to get a watch of this same level of quality. But for less than the cost of a well-used car, you can truly own your own piece of perfection with Heirloom Precision.

Conclusion

Want to take your own shot at having Jason Burton of Heirloom Precision work on a pistol project for you? Be sure to visit his website listed at the bottom of this article and check out the “Imagery” section to see some more of his projects and what he can do. If you do decide to commission an Heirloom Precision custom gun project and are lucky enough to get on the list, be prepared to be patient. He takes his time to get the projects “just right” — and this principle shows in his project guns. Works of art don’t happen overnight.

I can’t speak highly enough of the custom SA-35 from Heirloom Precision. The fact he took on the project speaks to the quality of the basic gun, and what he turned out shows the heights to which the pistol can be taken. Heirloom Precision’s Jason Burton chased perfection once again with this SA-35 project, and if you ask me, he captured it!

Editor’s Note: Be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in!

Join the Discussion

Featured in this article

Continue Reading

Did you enjoy this article?

447

447