How to Clean an AR-15 Magazine

November 17th, 2022

5 minute read

It’s easy to take AR-15 magazines for granted. When we train, we dump them on the ground and step on them, not thinking twice about it. We pick them up, load them and do it all over again. Lather, rinse, repeat.

The fact is, we don’t give AR magazine the respect they deserve. We just get annoyed — or worse — if they jam up and we curse the magazine for something we could have prevented. Magazines are an integral and important part of any firearm. They feed the machine. They deserve our respect.

The original M16 rifle, the military version of the AR-15, was first fielded in the 1960s with 20-round metal magazines. Not too long after, extended 30-round magazines began to appear. By 1980, the M16/AR-15 magazine was proposed to NATO to standardize magazines among NATO nations. You may recall hearing the AR-15 is a STANAG magazine. All that means is the AR-15 magazine was adopted under the Standard Agreement (STANAG) among NATO nations even though not all nations adopted the magazine.

Since then, the AR magazine has evolved past the traditional aluminum-bodied mags to include advanced polymer-bodied variants, steel, etc. Let’s take a look at how to care for them.

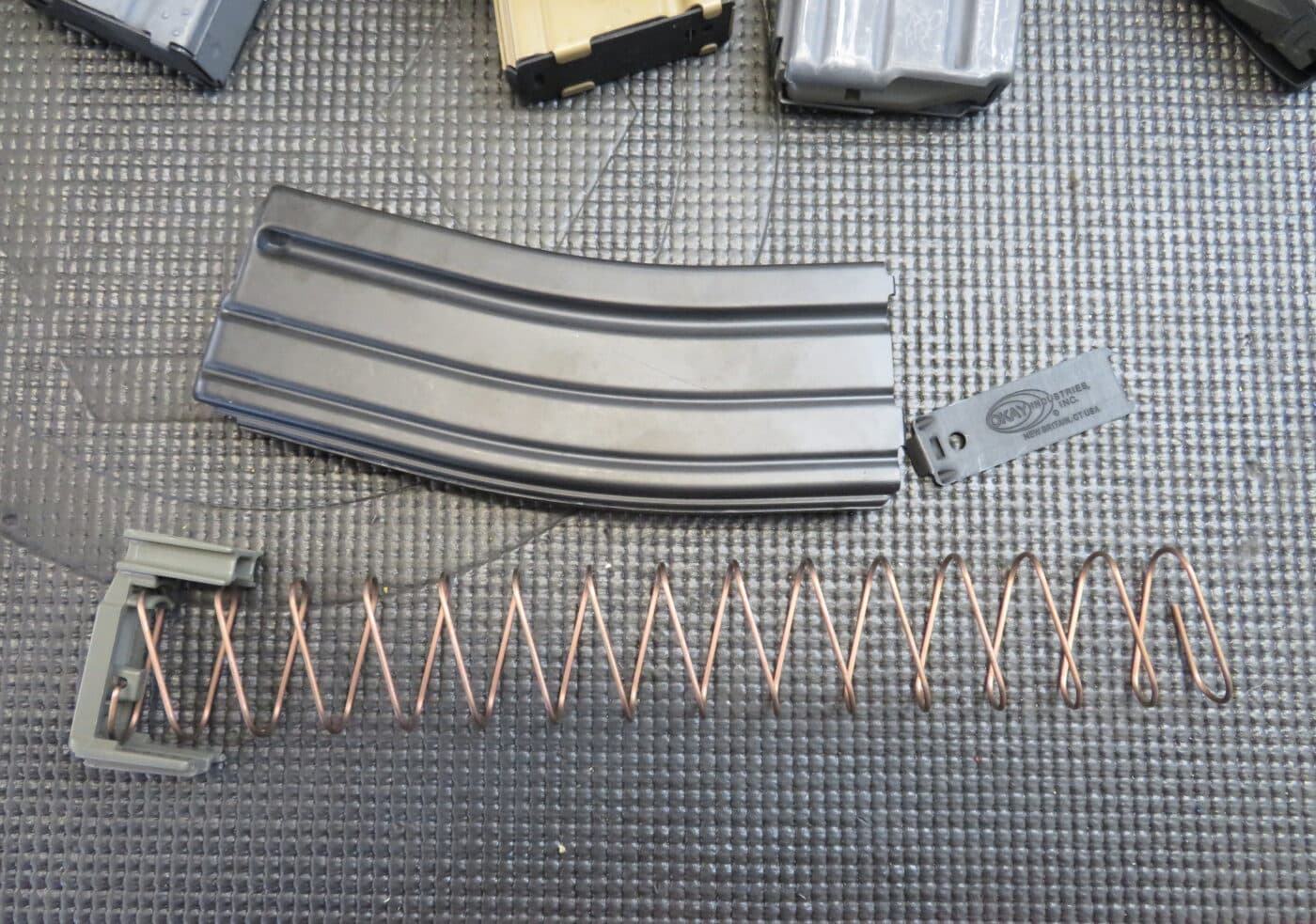

AR Magazine Disassembly

To disassemble a metal AR magazine, you need a cartridge or similarly sized punch. Press the bullet point, or punch, into the hole in the floorplate to release the floorplate and slide it off the magazine body. Remember the floorplate is under spring tension and the spring will shoot out if you are not prepared. You don’t want to poke your eye out, so wear safety glasses.

Next, work the spring back and forth gently as you pull it out of the magazine body. When you reach the follower, make sure you keep the spring and follower connected and wiggle out the follower. Congrats — you’ve successfully disassembled a metal AR magazine! It’s really that easy.

Cleaning Metal AR Magazines

Now, let’s move on to maintenance. Blow out the magazine body with canned air or use an air compressor. You can also run a clean cloth inside the magazine body. I use a long, flat-blade screwdriver to push the cloth into the corners and get out bits of yesterday’s lunch, latte spills, and the assortment of dirt, grit, sand, and dust.

Do not use any lubricant. Mixing oil and magazines is not a good idea. Oil attracts dust and dirt, turning into a cruddy paste that can foul the best-operating magazine. Next, examine the spring for any breaks or odd-looking bends. If you find any, deep-six the spring and replace it with a new one. Also, check the feed lips on the magazine body to ensure they are properly angled and smooth. If they are bent, send the magazine body to AR heaven and replace it. The follower, too, should be free of crack and chips.

Now reassemble in reverse order. Maggie would be proud. Don’t know who Maggie is? See page 26 in The M16A1 Rifle: Operation and Preventive Maintenance manual handed out to grunts in Vietnam circa 1969.

Polymer AR Magazines

When you think about modern magazines, the brand that comes to mind for many is Magpul’s PMAGs. Magpul began making their ubiquitous PMAGs in 2006 and has evolved this efficient and reliable design to the current Gen M3 model.

Many AR rifle manufacturers include a PMAG with their rifles, such as with the SAINT rifles from Springfield Armory. Magpul not only created a reliable polymer AR magazine, they also added texturing to the magazine for a better grip, a dust cover, an easily removable floorplate and stainless steel spring.

The secret sauce of the Magpul is its anti-tilt follower. Internal rails inside the mag keep the follower spring aligned, as well as prevent the follower from tilting. This set-up reduces jams and malfunctions. They are available in a range of capacities. Magpul PMAG Window mags have built-in window that immediately tells the user if the tank needs to be topped or if you are running on fumes.

I have probably trained more with PMAGs than any other magazine since they are nearly indestructible, reliable and very affordable. I also use the lower-capacity magazine when I’m shooting from the bench since the magazine is shorter and does not interfere with bench like a longer 30-round magazine can.

The design of the PMAG is slightly different than a metal G.I. AR magazine. The PMAG uses a dust cover that snap over the top of the magazine to prevent dust getting inside. I have a habit of accidentally losing these as soon as I open a new mag.

Disassembly and Cleaning of Polymer AR Magazines

Disassembling a PMAG is similar to a metal magazine. Just press in on the floorplate retainer button and slide the floorplate off the magazine body.

Watch out for the spring as it is under compression. The spring will slide out easily. Clean and inspect the same as you did with the metal magazine.

Conclusion

Your magazine can make the difference between your AR running and becoming an expensive paperweight. Remember, a happy AR magazine is a reliable AR magazine. Keep it clean and keep it happy.

Editor’s Note: Please be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in and discuss this article and much more!

Join the Discussion

Featured in this article

Continue Reading

Did you enjoy this article?

232

232