Soft Point vs. Hollow Point for Hunting

March 11th, 2024

9 minute read

I expected the elk to fold. It was just 40 yards off. Even in the 2 ½x Alaskan, its shoulder was big as a car door. Instead, it hopped ahead and stood, as if puzzled by the .270’s report. Aware the outcome of this drama depended on which of us recovered from surprise first, I fired again, this time into the spine. The animal dropped.

My first softnose had shattered on the scapula. None of its shards had damaged vitals.

Many years later, in Zimbabwe, I watched a pal send a 300-grain all-copper hollowpoint into an eland facing us at 50 yards. The .375’s blast sent the bull galloping off. We followed, expecting a short trail. But after a kilometer, prints showed the beast was keeping a brisk pace. How could that be? A few minutes on, there he lay.

[Follow Wayne’s advice on the best way to hunt elk before you head into the field.]

We dug the bullet from a hip. One of its petals had bent into the nose cavity, keeping the others from opening to over shank diameter. The bullet had driven the length of the huge beast like a solid.

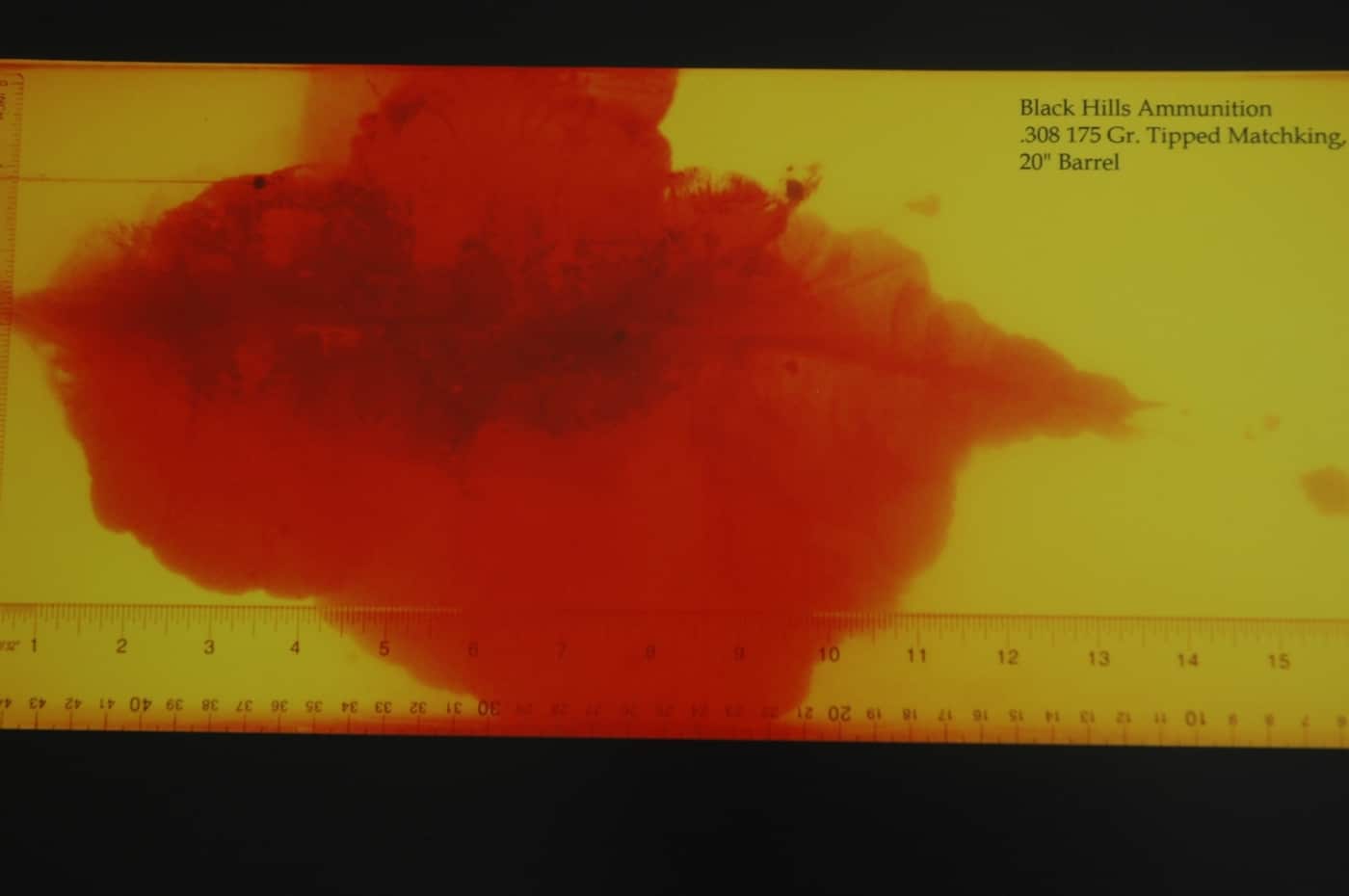

Expanding bullets can fail to behave as we expect in game. Animals aren’t homogeneous. Bones, muscles and gut contents don’t replicate ballistic gelatin. Impact speeds and shot angles vary. Mud, even water on an animal’s hide can affect bullet upset.

Thick lead bullets neatly killed bison, brown bears and Africa’s eland into the 1880s. Then small-bore cartridges fueled by smokeless powder pushed velocities high enough to foul bores with lead. Harder bullet alloys and shallow rifling improved accuracy; but slim, lightweight bullets lacked the killing effect of heavier missiles. Pass-through strikes wasted much of the energy imparted by high speed.

Looking Back

In 1882, the Swiss Army’s Lt. Col. Eduard Rubin designed a copper-jacketed bullet for the 8mm Lebel, the world’s first smokeless round. Other military powers followed suit. Steel jackets with cupro-nickel coating prevented fouling in U.S. .30-40 Krag bores, but not when bullets were driven faster from .30-06 loads. Tin plating helped, but was abandoned when it was found to “cold-solder” to case mouths. Incorporated in the jacket, tin fared better. Western Cartridge Co.’s Lubaloy jacket of 90 percent copper, 8 percent zinc, 2 percent tin, evolved into the 95/5 copper/zinc “gilding metal” alloy in modern jackets.

Jackets on both softpoint and hollowpoint hunting bullets are applied from the rear. Their noses are made to expand, to carve broad wound channels and, in deceleration, transfer their energy.

Most lead cores of jacketed bullets contain antimony to make them harder — typically 2.5 percent. A hard core best endures heat (bore friction) but fragments most readily on impact. Sierra achieves three levels of hardness in rifle bullets, with antimony proportions of 1.5, 3 and 6 percent.

Moving Forward

Stateside, the first jacketed softpoint hunting bullets were round-nosed, with lots of lead exposed to ensure upset at impact velocities of 2,000 to 2,400 fps — common for heavy Krag and .30-06 bullets at normal hunting ranges. But these bullets went to pieces at impact speeds topping 2,700 fps, when driven by Charles Newton’s potent .30 or the .300 H&H. To control expansion and gain a ballistic edge, Newton designed a pointed bullet with a copper wire nose insert that also prevented nose damage in the magazine.

The fast-stepping .270 Winchester and .300 H&H, both introduced by Western in 1925, called for thicker jackets to withstand ever more violent impact on game. Winchester’s Precision Point had a cone of jacket material over the bullet tip and anchored under the jacket proper. Upset began at three lead “windows” at this juncture. Peters’ Protected Point also had a nose cap. A driving band around the front third of the core and under the jacket was pushed rearward on impact, braking expansion. Each Protected Point bullet required three hours and 51 operations to make! A similar bullet without the band became Winchester’s Silvertip.

During the 1930s, Remington developed its Core-Lokt bullet, a mid-section jacket “belt” resisting core-jacket separation. Remington’s Bronze Point bullet had a conical tip metal tip that drove back into the core to prompt upset. Despite its armor-piercing look, this sleek missile could rupture violently at high impact speeds. Legions of polymer-tip bullets now share its peg-in-nose-cavity design. Their terminal action in game depends a great deal on cavity dimensions and how the tip’s stem fits, also on jacket thickness up front.

In my youth, hollowpoints were either open-tip match (OTM) bullets with a tiny hole in the nose, or light-game bullets built to expand quickly and/or fragment. Neither performed reliably in tough game. Match bullets might pierce, tumble or mushroom, depending on several variables. “Hunting” hollowpoints had thin jackets that extended above the cores. Impact shattered the jacket, exposing the core’s flat top, which yielded like the naked lead of round- and flat-nose bullets.

There were exceptions. Before WWII, Western Tool and Copper Works peddled a hollowpoint with a thick jacket and a small cavity that limited upset even at high-speed impact. Bitterroot Bullets wore ductile jackets of unalloyed copper as thick as .060, producing double-diameter mushrooms behind their modest nose cavities, with little weight loss. DWM had a “strong-jacket” bullet, its cavity lined with copper tubing.

The Choices?

Still, most hunters used softpoints for deer and bigger game. Early versions, like the bullet that failed me on an elk shoulder, were too lightly constructed for tough beasts. On deer they could be destructive. When hunters howled about ruined venison on deer shot with fast .270 bullets, Winchester fielded a mild 150-grain load clocking 2,675 fps. Nobody bought it. The contagion of higher velocity had taken hold!

It would bring stouter softpoints. In 1946 John Nosler hit a mud-encrusted moose several times with bullets from his .300 H&H. At last, the beast expired. John found his bullets hadn’t driven deep enough. So, he designed a softpoint with a gilding metal dam behind the ogive to stop upset — like the RWS H-Mantel. The heel remained intact to drive deep. Jackets on early Partition bullets were machined from tube stock and had a frosted exterior finish with a shiny belt, a tiny hole in the dam. Later jackets made by impact extrusion have a smooth, bright finish. There’s no hole. In the 1980s Lee Reed improved on the Nosler Partition with his Swift A-Frame, bonding the nose section.

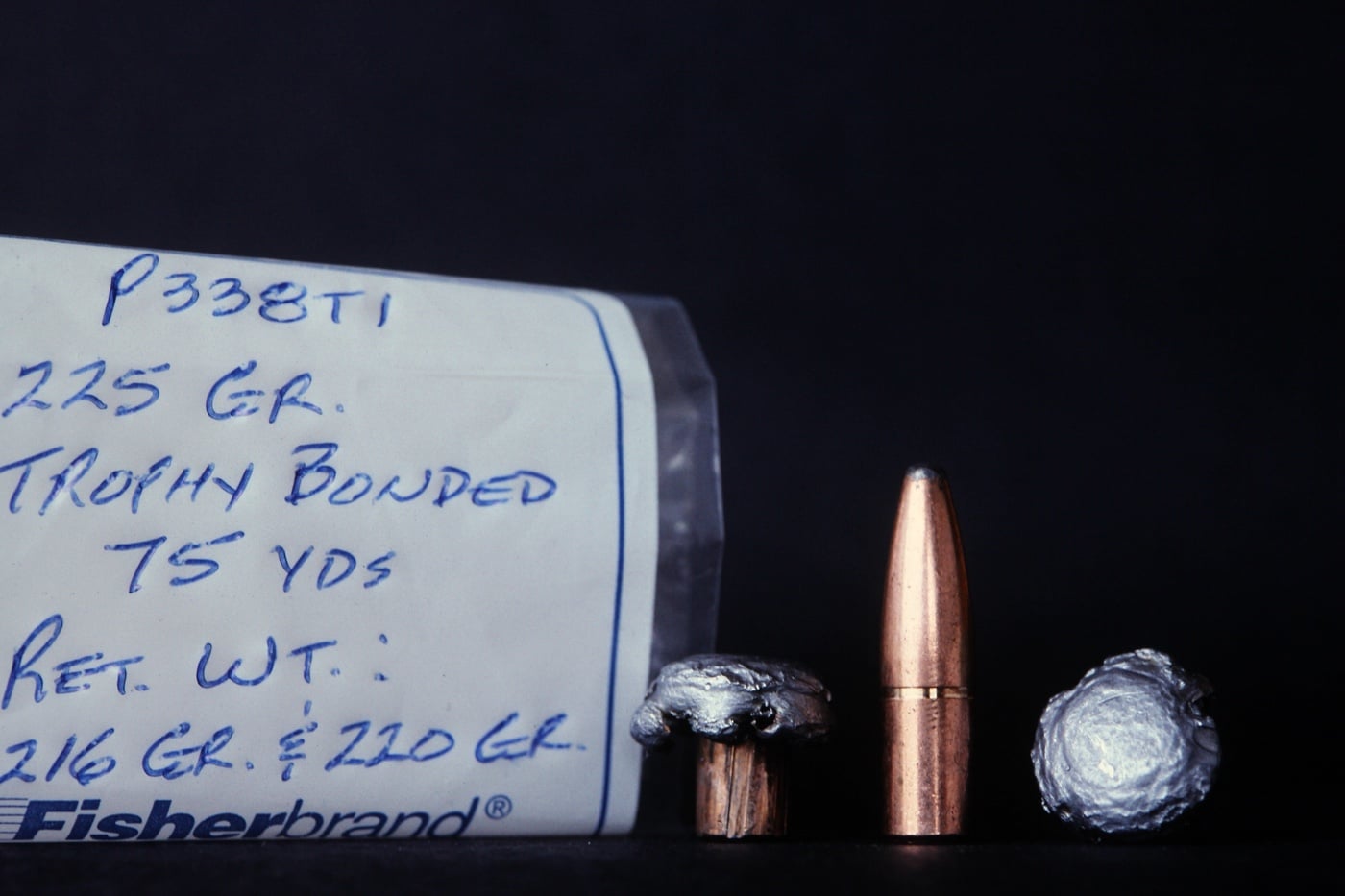

About that time bonding nose to jacket gained market traction in Jack Carter’s Trophy Bonded bullet (now made by Federal). Bonded bullets have proliferated — Federal’s HammerDown, Terminal Ascent and Trophy Bonded Tip, Hornady’s InterBond and DGX Bonded, Norma’s BondStrike and Oryx, Nosler’s Solid Base Bonded and AccuBond, Remington’s Core-Lokt Ultra Bonded, Speer’s Impact, Swift’s Scirocco, Winchester’s Dual Bond, Woodleigh’s Weldcore…

Mechanical “locks” also wed core to jacket — the inner belts on Peters and Remington bullets of the 30s, Hornady’s current InterLock. A swaged jacket ring helps secure the core of Speer’s Grand Slam.

Making the bullet’s heel less pliable than its nose helps it penetrate after high-speed impact, without impeding upset after the bullet has lost velocity at long range. Early Trophy Bonded bullets wore jackets of pure copper rod, progressively annealed to be harder at the thick base than at the nose. TIG (Torpedo Ideal) and TUG (Torpedo Universal) bullets by RWS have two cores, for a similar effect. The shank of a TIG has a funnel-shaped mouth to accept the coned butt of the front section. Upset begins at this juncture as well as at the nose. The rear core opens slowest because it’s hardest. A TUG’s rear section fits into a cavity in the front section. On impact, the nose gets slammed from both ends and opens violently. The shank powers on. Speer gave its Grand Slam bullet a two-part core, the rear section harder than the front.

A Hot Take

Hollowpoint bullets might still be relegated to ‘chuck pastures, were it not for an idea that took shape for Randy Brooks in 1985. He decided bullets didn’t need lead cores, that solid copper or copper alloy bullets could be made to fly accurately and expand reliably. The resulting Barnes X-Bullet had a hollow nose with scored petals that peeled back in the shape of an X. The later Triple-Shock (TSX) had driving bands that improved accuracy.

Solid-copper hollowpoints now issue from nearly every company that makes hunting bullets. They fly accurately and plow deep. Weight retention routinely nudges 100 percent! Copper (and similar gilding metal) bullets must be longer to equal the weight of lead bullets of the same diameter and shape. They typically deliver their best terminal performance within narrower “velocity windows” than lead-core bullets.

While tipped bullets predate WWII, only recently did polymer become useful tip material. Color-coded to brand or diameter, they’re cosmetically and ballistically attractive. Engineers like them, pointing out that bringing cavities to a uniform finish without a tip can be a chore.

In 2005 Hornady used a soft polymer to make pointed bullets for “deer rifle” cartridges like the .30-30. In tube magazines primers are jammed by spring pressure and recoil against bullets behind them, nixing use of traditional pointed bullets in popular lever rifles. The resilient poly tips on Hornady’s FTX bullets in LeverEvolution loads compress enough to be safe in tubes; but they resume conical form in the chamber. Like hard-tipped pointed bullets, they fly flat and retain energy well downrange.

Later, Doppler radar showed that bullets fired from long-range cartridges were reaching in-flight temperatures over 700 F. Result: poly-tip distortion, with steeper trajectories and diminished accuracy. Hornady developed a Heat Shield Tip, its glass transition temperature (at which polymer turns rubbery) eight times higher than that of ordinary tips!

“In-flight friction becomes a problem only at very high bullet speeds over long distances,” clarified project chief Dave Emary. “No bullet gets to 700 F quickly or stays that hot for long. Doppler hasn’t shown tip melt for any polymer inside 300 yards.” For shooters using the PRCs and similar cartridges at long range, Hornady’s Doppler trials produced its ELD-X and ELD-Match bullets. Similar bullets have since appeared from other manufacturers.

Conclusion

So, which is best for hunting: softnose or hollowpoint? I prefer heavy bonded softpoints for tough beasts at modest ranges. But solid-copper hollowpoints have become hugely popular. They’re much more suitable for big game than were jacketed hollowpoints of my youth. And they fly as flat as match bullets.

Tipped bullets — lead-core and solid-copper — have nose cavities. So, aren’t they hollowpoints, too?

Choices, choices.

No bullet can yet match the killing effect of sound shot judgment and good marksmanship.

Editor’s Note: Be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in!

Join the Discussion

Featured in this article

Continue Reading

Did you enjoy this article?

86

86