The Sounds of Silence: The Story Behind GSL Suppressors

December 9th, 2021

5 minute read

Suppressors seem to be that one category in the firearms world that are just difficult to really find any information on. Don’t get me wrong, the info is out there, but it can be quite tough to understand at times.

I decided I really wanted to dive into the suppressor world about two years ago, so I started doing a lot of research. What I was finding was most of the cans on the market seem to be the same designs with different names simply stamped on them. In fact, many companies are not even making their own suppressors. Yes, some looked fancier, but it seemed much of them really were the same designs from different companies.

This caused me to dig deeper, and I found a company called GSL Technology and the mastermind behind it all, Greg Latka.

The Mind Behind the Curtain…

Greg is a mastermind of suppressor technology. Holding nine patents in suppressors and suppressor design, Greg could be called the godfather of sound suppression. Greg started off in the aerospace industry. From a very early age, he was working in his father’s shop learning about manufacturing. At 25 years old, he started running his father’s shop. He was manufacturing components made out of Inconel, stainless steel, aluminum, copper, Titanium, Rene’ 41, brass and nylon.

In 1985, all Greg’s knowledge of these various materials, machining and manufacturing skills started to transfer into the firearms industry. Greg loves guns and wanted to experiment with suppressors, but quickly found that at the time there was almost no information available about them. So, he applied his technical skills and began experimenting with different designs.

A few years later, he came up with the helical design that became his first patent and led to the creation of his company, GSL Technology, in 1993. Greg was designing his suppressors under the GSL name while working with the company Gemtech, which commercialized the designs.

Greg later became the president of Gemtech, remaining in that position until 2016. He parted ways with Gemtech in 2016 and began the process of creating a public image for GSL Technology.

My Journey

So, what does this all have to do with my journey into the world of suppressors? Well, GSL Technology happens to be in my own backyard. A local Michigan company always gets me excited, and a local suppressor company with an owner that pretty much revolutionized the suppressor industry gets me even more fired up.

All this time I was searching for more info on suppressors, I had the mastermind behind some of the most famous designs right in my backyard. After a little digging, I was soon chatting with Greg himself on the phone and was quickly invited to check out their facility in Jackson, Michigan. I couldn’t wait to see how a suppressor was actually made and what went into them, so I jumped in the truck and headed out to the GSL Factory.

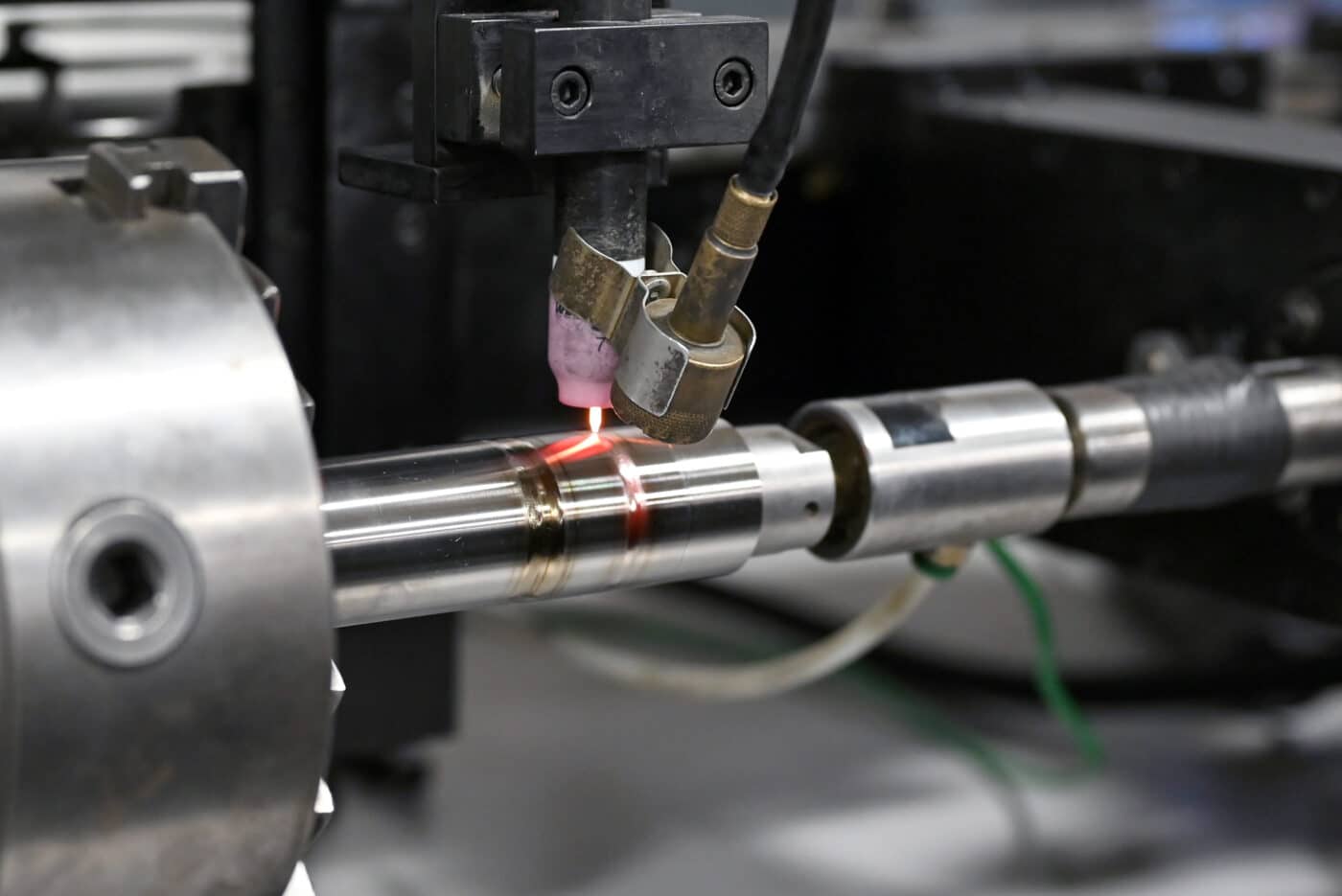

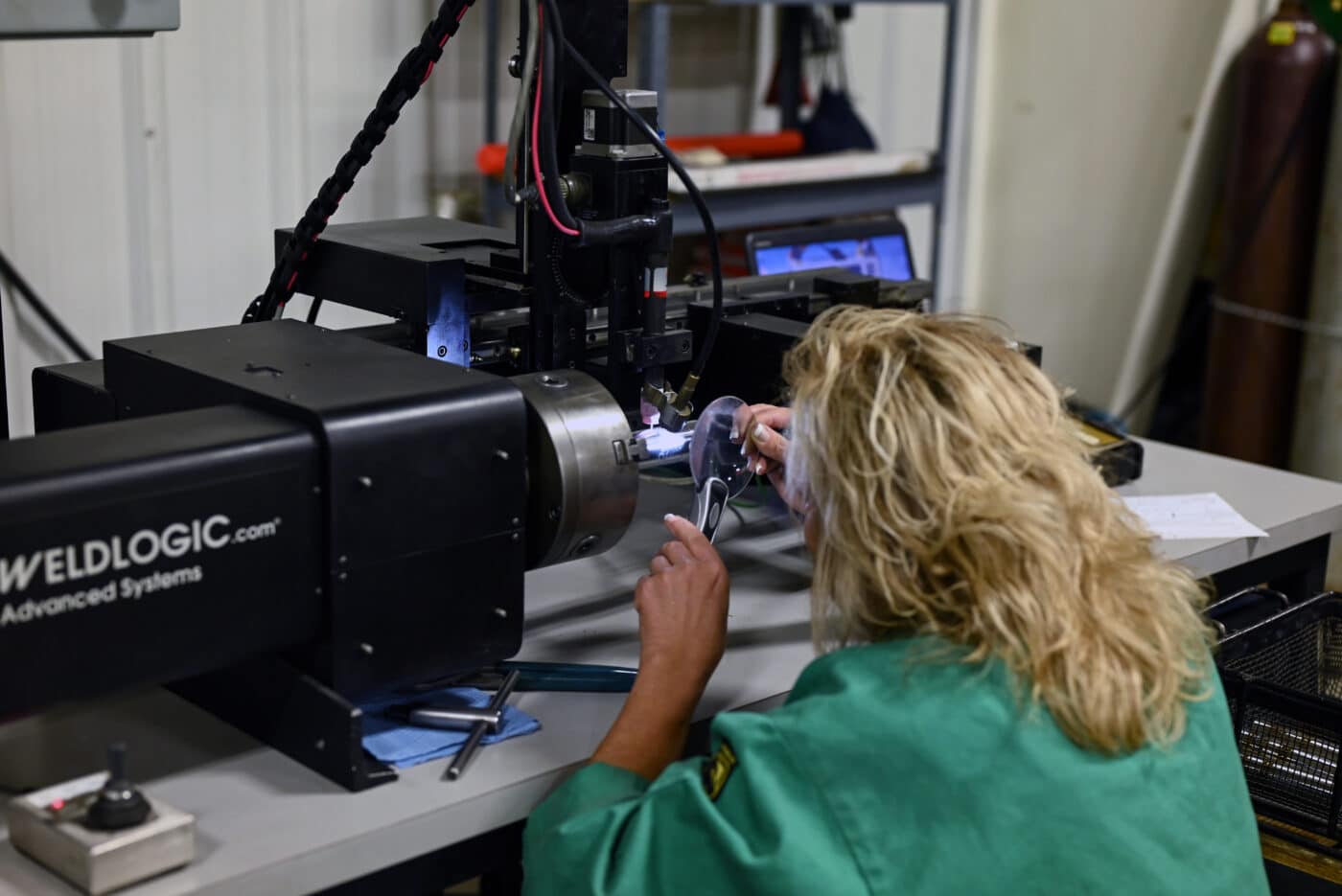

The facility is impressive. It’s 25,000 sq. ft., currently housing 18 CNC machines along with 25 secondary support machines including lasers and a fully automatic welder. The machines looked like an army ready for battle in perfectly straight rows — every single one of them with their own job to do. There were various metals being cut and drilled and chunks of metal becoming incredible little baffles and washers.

I was in awe of how clean everything was and just how much was going on in the factory. I guess the efficiency and cleanliness really shouldn’t have been a surprise since the shop is a certified ISO-9001-2015 rated quality facility, which is the highest quality rating a company can achieve.

Greg took me around the entire factory where I was able to meet many of the machinists, welders, engineers and quality-control employees. In speaking to them, I learned that everyone loves working for GSL and they all seemed to think of their fellow employees as family. I also learned that Greg has a fatherly role there. GSL Technology has some of the most loyal and dedicated employees I have ever observed.

The Details

I really wanted to see how these suppressors were made, from start to finish, so Greg ran me through the entire process. From raw materials to a finished suppressor, GSL does it all in-house. I was ecstatic when I came to the far end of the facility and saw the GSL range/testing area built right into the factory, with a bunch of different guns lying on the table all with different suppressors attached to them.

Greg walked me through his patented washer retention system, which completely eliminates the suppressor “walking off” the barrel. Then, it was time to test some cans. It may have been one of the coolest shooting experiences I have ever had — shooting all these different suppressed guns in a factory that was making the same suppressors literally right behind me.

The sound of brass hitting the floor and the machines cutting metal turned into a perfect symphony and something I have never experienced before while shooting indoors. Nearly no noise coming from the gun I was firing and being able to hear the firearm functioning and each empty cartridge case hitting the floor was a true pleasure.

Conclusion

The factory tour took me from being interested in suppressors to being obsessed with them. The work and technology that goes into designing and manufacturing a suppressor is incredible. GSL Technology is absolutely killing it right now with a bunch of new can designs that keep pushing the limits of technology and sound suppression.

GSL Technology is a veteran in the suppressor industry, having operated behind the scenes for almost 25 years. But the word is out, and they are ramped up to become the top suppressor company in the industry in the next few years. Find out more about GSL Technology and see their incredible line of suppressors by clicking the link below.

Editor’s Note: Please be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in and discuss this article and much more!

Join the Discussion

Featured in this article

Continue Reading

Did you enjoy this article?

65

65