What Is a Mid-Length Gas System? Splitting the Difference

March 24th, 2023

5 minute read

One of the frequently misunderstood aspects of the AR-15 is the gas system operation. In this article, Robert A. Sadowski answers the question of what is a mid-length gas system and how it compares to full-length, carbine and ultra-short SBR-style systems.

It happens in milliseconds. In fact, it happens faster than you can blink. As the gas system in an AR-15 chambered in .223 Rem/5.56 NATO uses the high-pressure gas from a fired round to cycle the action, your trigger press initiates the cycle of sending a projectile downrange, in addition to ejecting the spent case and chambering a fresh cartridge.

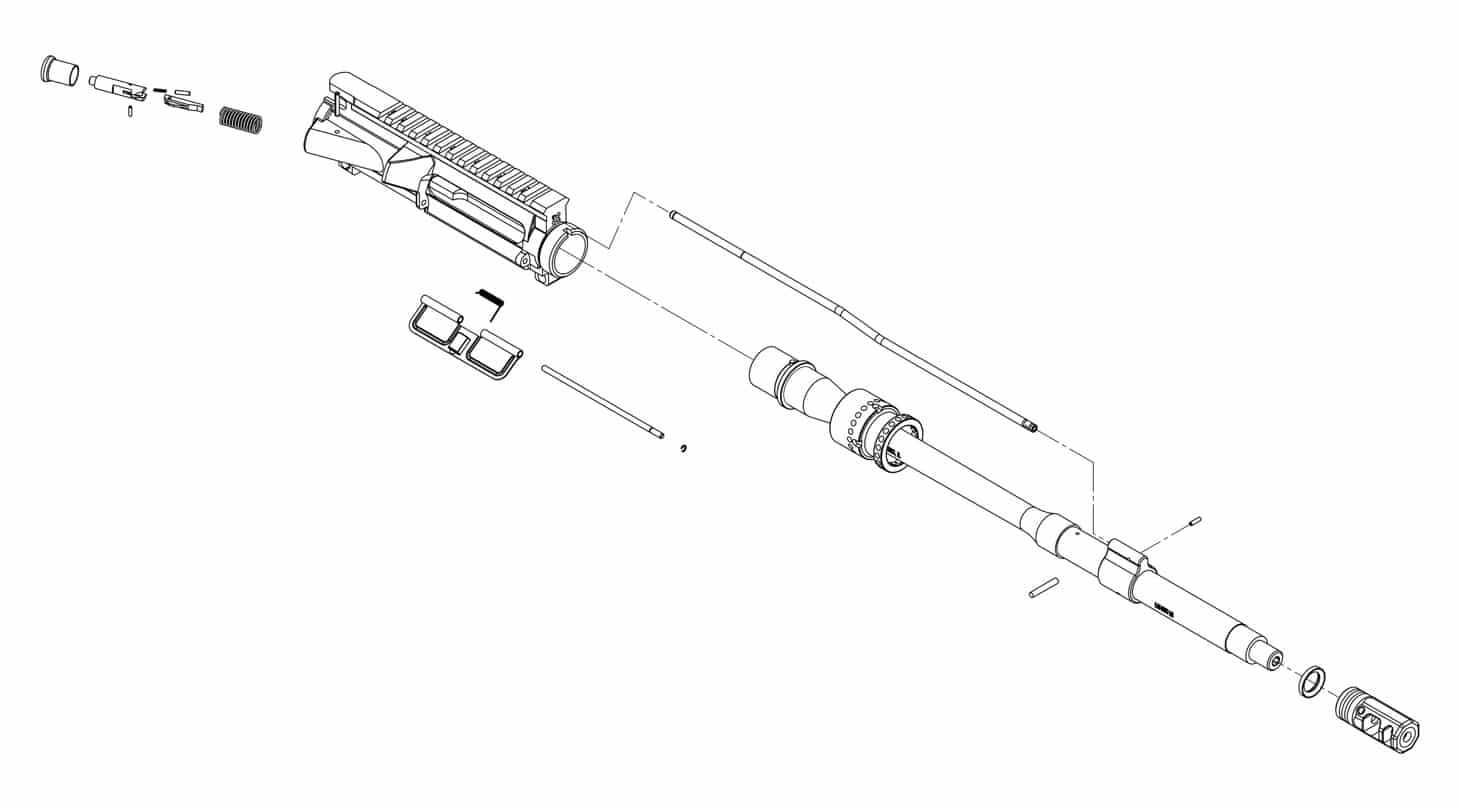

A port or small hole in the barrel vents gas through the gas block and into a gas tube. The gas flows through the tube, where it then meets up with the gas key on the bolt carrier group, or BCG as it is often known. When the gas hits the gas key, it pushes the BCG back against spring pressure to cock the hammer and eject the fired case. The now-compressed spring in the buffer tube then pushes the BCG forward as the BCG strips a round from the magazine and chambers the cartridge for the next shot. This is the basic operation of the direct gas impingement system (DGIS) on standard AR-15 platforms.

So, why does the length of the gas system matter? Simply speaking, the length of the gas system is measured from the receiver to the gas port. And, the length of the gas system has a profound impact on the operation of the gun, so it is important to properly match the length used to the gun.

Original military M16 rifles were equipped with 20” barrels. These rifles use a rifle-length gas system — the longest found on production AR-style firearms. To make the AR-15 more compact, barrel lengths have been shortened, and as a result, so have the gas system lengths. There are three primary lengths of AR-15 gas systems: Carbine, Mid and Rifle (and then ultra-short ones for specialty short-barreled-rifle variants). The length of the gas tube or system is directly related to the length of the barrel.

Dwell On This

The reason gas tube lengths and barrels matter is due to “dwell time.” Dwell time is the length of time that the bullet is in the barrel after it has passed the gas port. In the ultra-short barrels — typically from about 7” to 10” — the dwell time will be shorter since the bullet has to travel less distance. It’s the opposite in a longer-length barrel; dwell time is longer because the bullet has to travel a longer distance.

Here’s where the balance between gas system length and barrel length comes into play. If too much gas flows through the system, the receiver can become battered, causing excessive recoil and wear and tear on the AR. If not enough gas flows, the rifle may not cycle or could cause failure to feed (FTF) or failure to eject (FTE) malfunctions.

Gas System Length And Barrel Length Relationship

| Gas System Type | Barrel Length | Gas Port Distance |

| Ultra-Short Length | < 10″ | 4″ |

| Carbine-Length | 10″ to 18″ | 7″ |

| Mid-Length | 14″ to 20″ | 9″ |

| Rifle-Length | > 20″ | 12″ |

Like the rifle-length gas system, the carbine-length gas system has been around for a long time. The CAR-15 was a shortened M16 with a 10” barrel. Cutting the barrel’s length in half from the rifle created an obvious need for a new, shorter gas system. As the platform evolved into the M4 Carbine with a 14.5” barrel, the carbine-length gas system became standard equipment on U.S. military guns. The solution is this simple since the size of the gas port and the cartridge being fired also factor into dwell time.

Goldilocks Zone

Commercial AR carbines are required to have a minimum barrel length of 16” to avoid the red tape of the National Firearms Act (NFA) to make it a short-barreled rifle (SBR). Initially, many manufacturers used carbine-length gas systems, and in all fairness, those rifles worked. Nevertheless, it was not always a perfect solution.

However, to better match the gas system to the 16” barrel length, the mid-length gas system was developed and applied to rifles such as all the SAINT AR-15 variants. The mid-length system offered several benefits. For example, mid-length gas systems offer less recoil than a carbine-length system, making them more comfortable when shooting. Carbine-length gas system guns have relatively snappy recoil compared to rifle-length and mid-length system equipped guns.

Mid-length gas systems make the 16” barreled rifle function more reliably. The slightly longer mid-length gas tube creates more dwell time, which optimizes the rifle’s cycling so it runs better. Much ink has been spilled about the perceived reliability of the platform. Matching the gas system to the barrel length is one of the things you can do to make sure the gun will run reliably.

The longevity of the rifle also increases because the rifle is cycled with less pressure, so parts last longer. The rifle-length is just too long for some barrel lengths and the carbine-length increases recoil and cycling speed, but the mid-length is just right.

The secret sauce for optimal operation is the relationship between the gas system length and barrel length. Optimal performance is best when the barrel length is closer to the middle of the functional range of the gas system, e.g. a mid-length system will work better with an 18” barrel than a carbine-length system. The gas port size needs to be considered, but the gas system length and barrel length relationships are important.

A Great Combination

That’s the reason why Springfield Armory features mid-length gas systems. Better performance, less wear and tear on parts, less felt recoil, and good accuracy. There are many variables that go into manufacturing a reliable AR-15, and a mid-length gas system with a 16” barrel make for a great combination.

Editor’s Note: Please be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in!

Join the Discussion

Featured in this article

Continue Reading

Did you enjoy this article?

262

262