MrMichaelActual

Custom

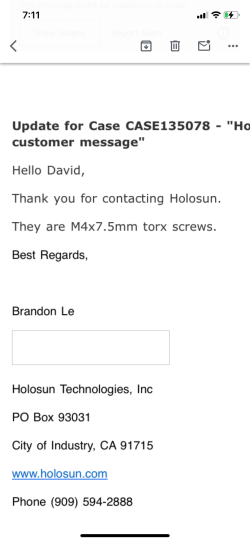

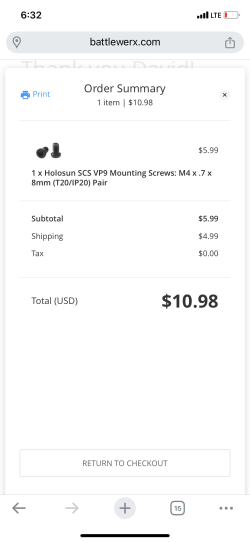

Holosuns do all come with pretty good hardware, but a lot of us go for buying mounting screw kits from several of the places mentioned above, perhaps just a bit higher quality material. Personally, if I Untorqued and torqued more than a time or two, say to change batteries, I would change screws also. Metal gets fatigue when torqued and there is a limit, although we may not know what it is, to how many times it will withstand torquing. Holosun does have a recommended torque and as you noted they do use a drop of dried Blue loctite.

If you are going to get into this and are able to do so, you should buy a Wheeler F.A.T. wrench and maybe some fixitsticks. The right tools do matter.

Like the good folks above pointed out, anything wetish can be a lube temporarily.... don't wet lube your screws then torque.

Were you able to get the screws out?

Cheers Dave!

If you are going to get into this and are able to do so, you should buy a Wheeler F.A.T. wrench and maybe some fixitsticks. The right tools do matter.

Like the good folks above pointed out, anything wetish can be a lube temporarily.... don't wet lube your screws then torque.

Were you able to get the screws out?

Cheers Dave!