pmmiller52

Alpha

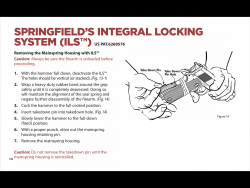

I’m a brand new SA 1911 9mm Range Officer owner. I’m working through initial total disassembly for cleaning and tuning. in attempting to remove the mainspring housing I’m finding the step of inserting the take down pin into the take down pin hole to be very difficult. I don’t want to damage anything by forcing the pin into the hole. Can anyone tell me how much force should be needed to insert the pin? Could it be that on the first removal it is more difficult or is there some trick to it? Help please?